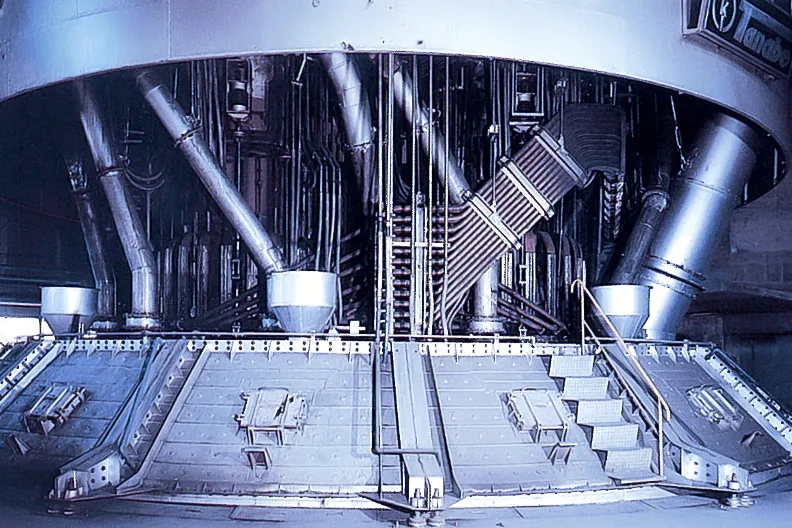

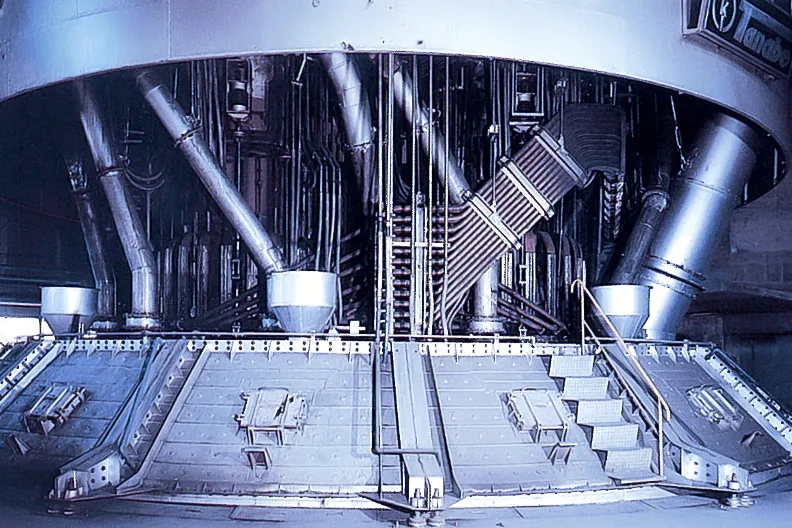

The melting furnace is a device that heats and melts raw materials at high temperatures, and Tanabe offers three main types of melting furnaces: electric resistance, plasma, and burner types. Among these, the electric resistance melting furnace is known for its versatility and proven performance. It generates Joule heat by passing electricity directly through the raw materials or molten slag, achieving high thermal efficiency. Additionally, since no open arc is generated, it allows for quiet operation, produces minimal exhaust gases, and enables compact processing equipment.

There are various types of melting furnaces depending on the application. For example, the plasma melting furnace is used for processing municipal waste incineration ash, where the raw materials are heated and melted by a high-temperature plasma jet. On the other hand, the burner-type melting furnace heats and melts the raw materials using the combustion heat and radiant heat from burners, making it particularly suitable for small to medium-sized incineration facilities.

Melting furnaces are capable of processing raw materials through reduction reactions, volume reduction, and detoxification, and they offer a lineup tailored to various industrial applications. Moreover, Tanabe not only provides the melting furnace itself but also offers auxiliary equipment, allowing for optimal design tailored to customer requirements. Furthermore, Tanabe provides extensive after-sales services, including regular maintenance, spare parts supply, and modification work, ensuring the best operational environment.